Supervisor

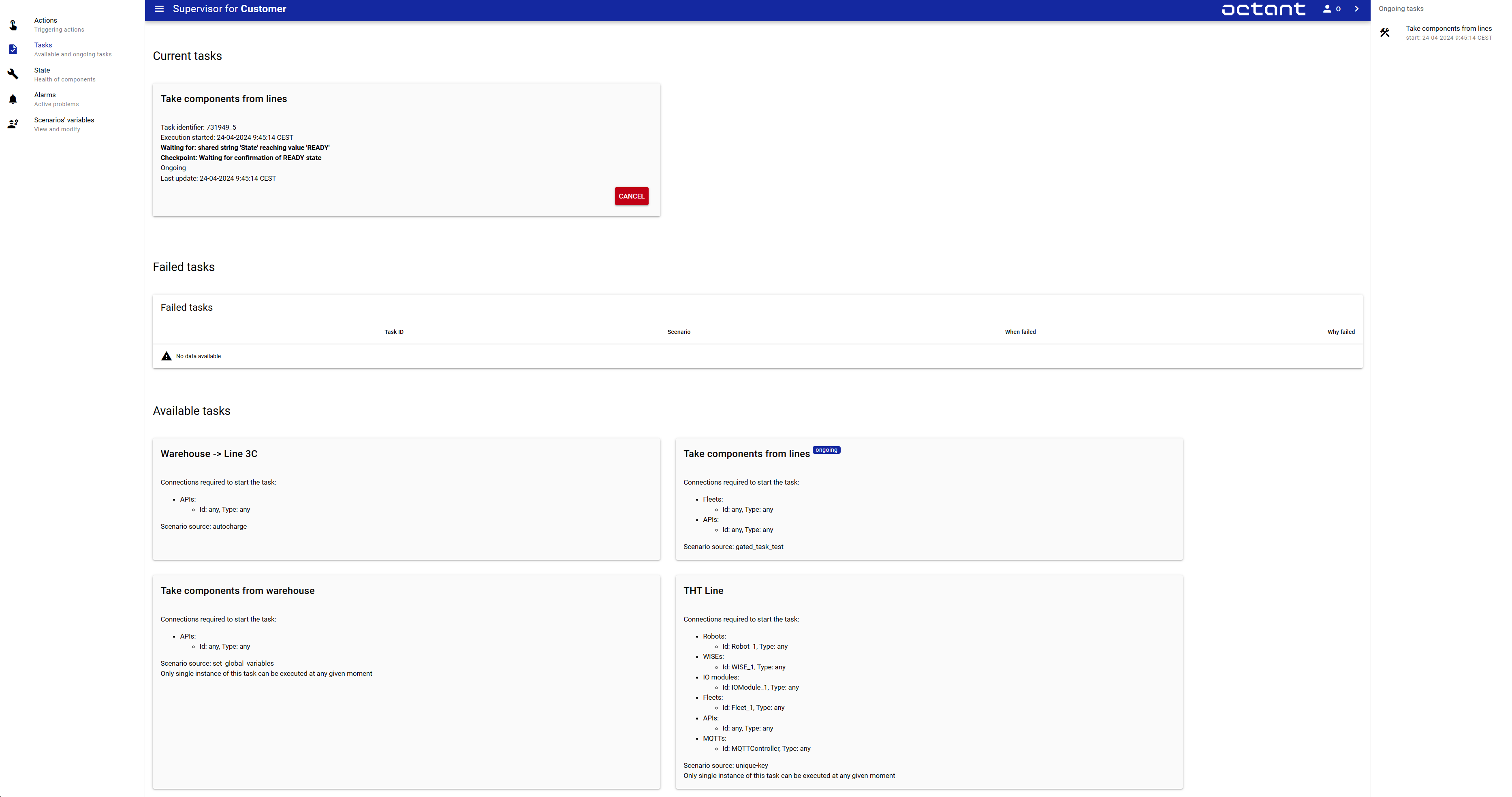

Supervisor increases the efficiency and functionality of mobile robots and enables process automation through the handling of personalized, complex scenarios.

Supervisor increases the efficiency and functionality of mobile robots and enables process automation through the handling of personalized, complex scenarios.

Thanks to personalized scenarios, Supervisor effectively automates even the most complex processes. Through integration with production management systems such as ERP/SAP and dedicated user panels, Supervisor enables synchronization of production activities, leading to smooth data flow and improved efficiency of mobile robots in intralogistics areas. The software supervises and coordinates the work of robots, IoT devices, and fleets, allowing for more efficient resource utilization and conducting some processes without human intervention.

Benefits:

Efficient robot operation

Automatic triggering of transports

Unmanned handling of some processes

Implementation of complex transportation tasks

Utilization of different types of robots in one workspace

Automatic handling of additional infrastructure, e.g., machines, scanners, sensors, and gates

Communication with ERP/SAP

Software facilitating and enhancing the capabilities of autonomous robots in the transportation process.

Code-like scenarios

The ability to generate process scenarios using the Kotlin language

Manageable control panels

Flexible operator panels tailored to the process needs

Launching transport scenarios

A variety of options for generating and executing transport tasks

Communication

Ability to connect to ERP/MES production management system

Hardware requirements:

2x2,5Ghz, 16GB RAM, 100GB HDD

Delivered as a Docker image.

Must run on site.

Autonomous forklift

Over the course of the year, it transported over 10,000 tons of products and completed 15,000 100-meter runs, reaching areas where conventional forklifts cannot fit.

Automated transport of semi-finished products from the preparation area to the production line.

3 MiR robots with Dorsal docking modules ensure smooth delivery of components, aiming to increase the efficiency of the production line by delivering parts at the right frequency.

Autonomous waste disposal - up to 132,000 liters per day

A system of 3 autonomous robots manages 24 containers and 4 bins located in docking stations positioned at 20 locations in the warehouse.